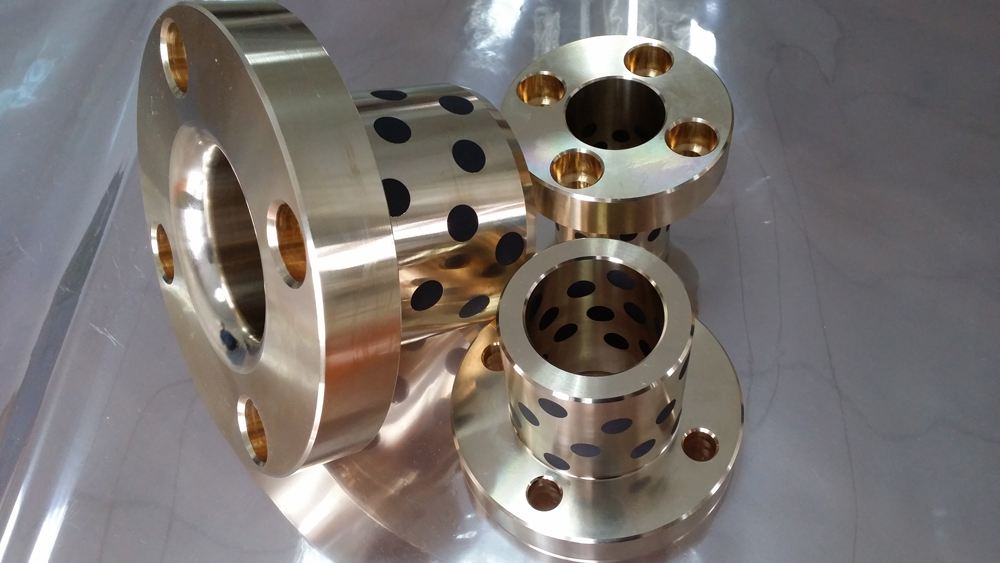

Solid self-lubricating bearings and shaft sliding friction occurs, and the shaft in the course of the operation to pass the torque and movement, so the hardness of the shaft material and strength requirements, JDB-1 self-lubricating bearings generally use metal grinding parts, hardness HRC40 °; SF-1 requires a lower, generally 45 # steel can also be used. For friction and wear performance is mainly dependent on the performance of solid lubricants, solid self-lubricating bearing bearing capacity, high rotation accuracy, solid lubricating film with impact resistance.

Solid

lubricating film for the solid self-lubricating bearing face material

itself has a good self-lubricating properties, in the initial stage of

the work gradually through the wear and tear self-lubricating material

gradually transferred to the surface of the grinding parts of the

surface of the formation of hard lubricants; This

is a certain requirement for the roughness of the face of the

workpiece, generally in the range of Ra0.4 ~ 1.6; too bright or too

rough surface is not conducive to the transfer of lubricant to the face

of the formation of the lubricating film; Solid

lubricating bearings are generally required to be grinding surface to

the polished surface; when the solid lubricating film is fully formed,

the movement between the shaft and the bearing has actually been

transformed into the friction between the lubricating film and the

bearing movement, the shaft is not directly Contact with the bearing surface.